Learn AR-15 disassembly – how to field-strip and completely disassemble your AR and get it all back together again – for routine and advanced cleaning, maintenance and repair.

The basic AR-15 disassembly is field-stripping, where you take the rifle apart well enough to clean it. Cleaning is important. Have you seen the movie Major League? Charlie Sheen (who pitched in college, by the way) is a rocket launcher-armed pitcher who can’t hit the strike zone. He can’t see. He gets glasses, very ugly glasses. The coach remarks “It’s important to see.” One of the other players counters with “It ain’t that important.”

Stripping to clean is that important.

Field Stripping

In order to safety-check and to clean or begin armorers work, you must be able to field-strip the AR. Place the safety on “SAFE.” If there is a magazine present, remove it. Pull the charging handle to the rear and lock the bolt open. The bolt hold-open is the lever on the left side of the upper receiver. Keep the charging handle pulled to the rear.

Either pull the wider, serrated paddle part of the bolt hold-open out from the receiver, or press the smaller, lower portion of the bolt hold-open into the receiver body. Ease the bolt forward. Once it stops, you can release pressure on the bolt hold-open. (If you did not pull the charging handle back far enough, the bolt may appear held open, but will snap forward with any slight vibration. Be careful until you have looked at the bolt.)

Press the charging handle forward until it locks in place. Look into the chamber. Use a light if you need to, as an oxidized brass case, or a steel case, may be so dark that you’ll overlook it except in bright light. If your finger fits, reach in and check the chamber. (The ejection port is small, and not many people have fingers small enough to reach. The only method most can use is to reach up from the magazine well.)

With the chamber verified empty, close the bolt. It is best to build correct habits even while doing administrative tasks on the rifle, so close the bolt by pressing or slapping the hold-open lever. The bolt will crash closed. Stop cringing, that is the way it operates when you fire it, so closing the bolt that way is not abuse.

Press the rear takedown pin from the left to the right. Pull it until it stops at its full movement. The upper will hinge away from the lower. (Be careful to control the upper so it doesn’t swing up and strike you in the face.)

Pull the charging handle halfway back. Then grasp the carrier and pull it back, down and out of the rifle. Place it on the table. Pull the charging handle back until it stops, then pull it down and out. Press the front pivot pin from the left to the right until it stops.

The upper and lower receivers can now be separated.

In the field, or in a range class, this is all you need to do to gain access to the working parts for a quick cleaning. From here, aerosol cleaners and lubricant can clean what needs to be cleaned, lubed and reassembled.

But, since you have it apart right now, let’s do a quick inspection and functions check. After all, if you own an AR, or plan to be doing any work on them, these are things you’ll be doing on a regular basis. Best to learn how right away.

Operational Checklist

An operational checklist is a process whereby you inspect a rifle for proper fit and mechanical function, without firing it. Any fault you covered in an operational check should be corrected before that rifle can be used in a match, practice or for defense. Right now I’m not going to cover the causes and corrections of the faults found, only the process.

Faults uncovered are divided into two groups: those that require immediate correction (or at least correction before use) and faults that can be overlooked in an emergency, where the fault would not impair function sufficient to prevent use as emergency equipment. An example of a fault in the first group would be a rifle lacking sights.

There are very few faults that fall into the latter category, as a rifle as emergency equipment is not like a fire extinguisher that only has 87% of its charge. A fault in the second category would be a stock that is present, but loose. Usually, most faults on firearms are an “all or nothing” situation, especially defensive firearms.

Properly done, an Internals/Selector check takes two minutes, and you should get into the habit of doing this check every time you pick up your AR, or any other firearm, for that matter. I know, I know, you did it last week, and the week before, why do it again? Because since the last time you may have been doing some work on your AR, got interrupted, and left it as-is. Having now forgotten, if you don’t do a check, you may be depending on an inoperative rifle.

Internals Check

We’re already at the field-stripped stage, right? If not, move back up, read and field-strip your rifle.

Inspect the lower.

Make sure the hammer springs are on either side of the trigger pivot, and above the trigger pivot spring. Check to make sure they are intact, and one or both legs are not broken. Look at the hammer and trigger pivot pins, and make sure they are flush to the outside of the lower, and not protruding. A pin that sticks out indicates it is not secured, meaning some spring in there is out of place. Move the selector back and forth from “Safe” to “Fire” (and on to “Auto” or “Burst” if the rifle/carbine in question is a select-fire weapon) and visually inspect the lower to ensure there are no debris, dust, lint, threads from cleaning patches or loose primers present.

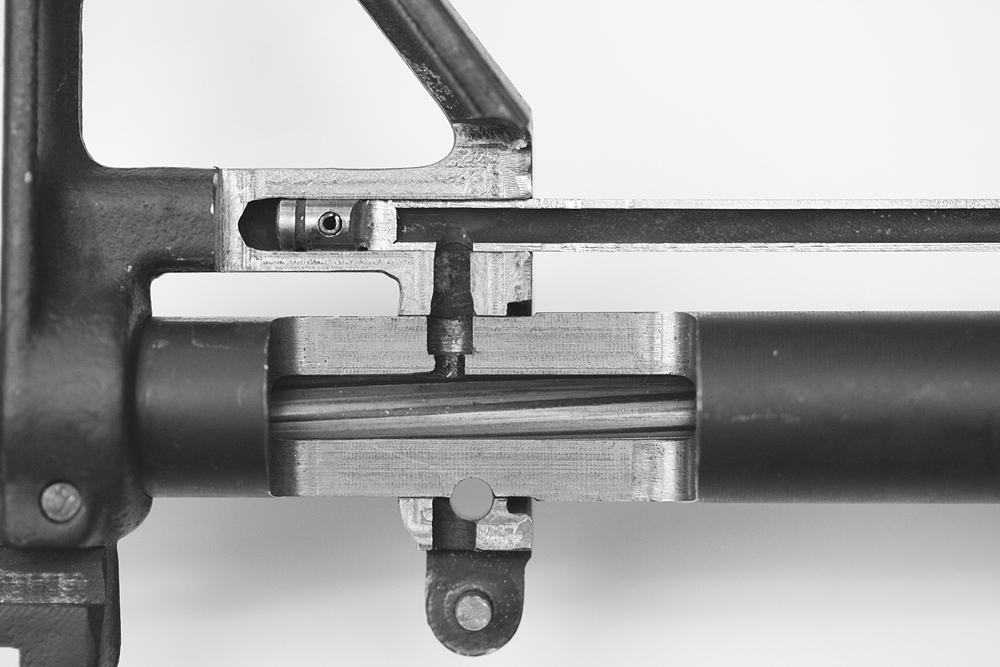

Inspect the carrier. Grasp the carrier in one hand and the carrier key in your other hand. Try to move the key. Any movement at all means the rifle must be pulled from service until the key can removed, reinstalled and locked in place.

Inspect the bolt. Are the locking lugs clean and oiled? Any visible chips or cracks in the lugs require the rifle to be pulled from service until the bolt can be replaced. Does the ejector move in and out of the bolt when pressed with a small rod? (It won’t move under finger pressure.) Does the extractor flex when pushed? Too much or too little movement requires service on those parts.

Finally, pull the bolt forward in the carrier, and stand the bolt on its head. If the weight of the carrier causes the bolt to collapse towards the tabletop, the gas rings are worn and must be replaced.

Install the bolt back into the rifle and close the action. Close the upper to the lower and press the takedown pins back in place.

Selector Check, SEMI

Lock the bolt back. Inspect the chamber. Once clearly unloaded, press the bolt hold-open lever and allow the bolt to close under its own power. Move the safety to all positions. If it does not move, the problem must be found and corrected.

Press the selector to SAFE. Press the trigger with 10 to 12 pounds of force. The hammer should not fall. If it does, the trigger mechanism is defective, broken or improperly assembled, and the fault must be found and corrected. Release the trigger.

Press the selector to FIRE. If the hammer falls when the selector is moved, but before you press the trigger again, again the mechanism is either defective or improperly assembled and must be corrected. The selector function when on SAFE acts by blocking movement of the trigger. If the hammer falls, the selector did not prevent trigger movement, and when it was moved to FIRE the trigger completed that movement, allowing the hammer to fall.

With the selector on FIRE, press the trigger. The hammer should fall. If it does not, it is obviously not ready for issue, use in a match or for defense and must be corrected. If it does, now hold the trigger back. Grasp the charging handle with your other hand and cycle the bolt. Gently release the trigger.

You should feel it “click” as the hammer resets off the disconnector hook and onto the sear nose of the trigger. If there is no click, open the upper receiver. If the hammer is forward, or still caught on the disconnector, the mechanism is either improperly assembled or the parts mis-timed. Find out why, and correct it.

If the rifle passes the SAFE and FIRE checks, you must then check for disconnector retention during cycling. Cycle the charging handle to cock the hammer. Press the trigger and allow the hammer to fall. Hold the trigger back. Briskly pull back and release the charging handle, allowing the bolt to close under the full power of the buffer spring. Gently and slowly release the trigger.

The hammer should “click” from the disconnector to the trigger sear. If it does not, it must be adjusted. Then leave your finger off the trigger and briskly cycle the charging handle and allow the bolt to crash home at full power. Then dry-fire again. If the hammer has followed the bolt forward, the disconnector is (again) either improperly installed or mis-timed and must be corrected.

All those faults are covered in their own chapters, so read on.

Visual Inspection/Tightness

Inspect the fit of the upper to the lower. While a certain amount of looseness is often customary, and does not hinder proper function, an excessively wobbly fit indicates either serious wear or a dimensional mis-match. Excessively loose upper-to-lower fits can be solved by exchanging uppers until the uppers and lowers you own all fit properly.

I have this discussion often in the law enforcement classes: While “mix-and-match” rifles will almost always function properly, remember that the accuracy of a rifle goes with the upper, not the lower, but the felt trigger pull goes with the lower. A matched upper and lower used in a precision marksmanship role must not have the upper and lower swapped with patrol car issue rifles, or the accuracy and/or trigger pull of the precision marksmanship rifle will be lost.

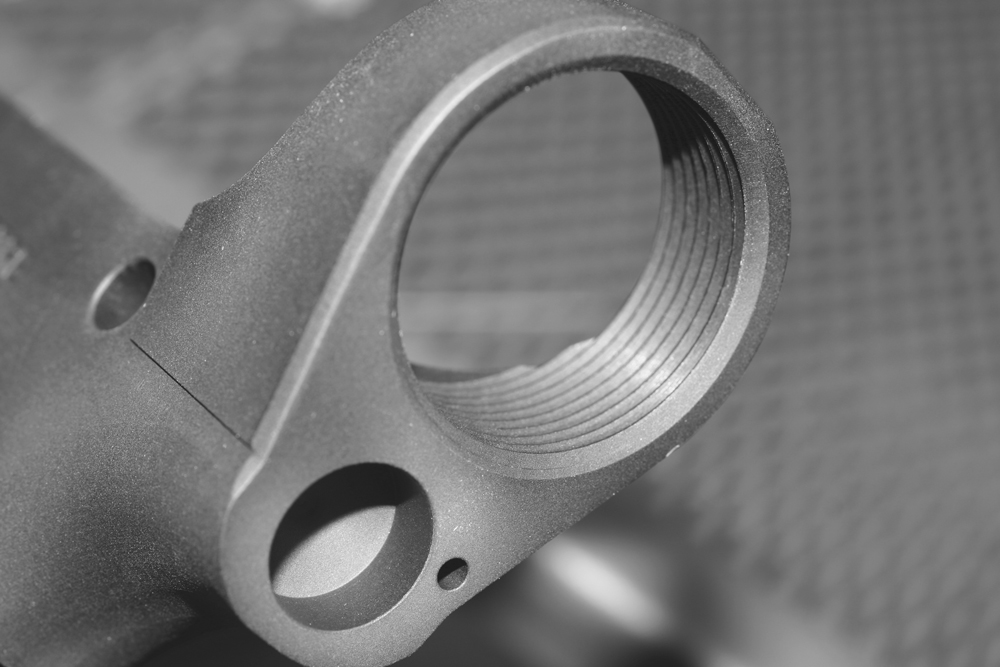

Inspect the stock for tightness. Solid stocks (A1 and A2) should be immovable. Tele-slider stocks will usually have some wobble in the sliding portion, but the buffer tube itself must be tight. Loose A1/A2 stocks or loose tubes in either rifles or carbines must be corrected.

Inspect the barrel for tightness in the upper receiver. An upper with a loose barrel cannot be accurate, and the cause must be found and corrected.

Inspect the front sight for tightness to the barrel.

Inspect the sights to be sure all parts are present and that any paint markings to indicate zero settings have not been disturbed.

Visually inspect the rifle to see if there are any obvious signs of having been dropped, abused, altered or parts exchanged. Also, check the serial number to ensure it is the weapon being issued and signed for.

Range Analysis

Range analysis differs from the bench checks you’ve done, in that you are firing the rifle.

A range checklist is done to ensure that a particular rifle functions perfectly, is zeroed and that all accessories on it are working within accepted limits. A range test-fire session is performed to ensure that corrections, alterations or repairs have been correctly performed. As an example, a rifle with a worn barrel that does not shoot accurately enough will require a new barrel.

Once installed, the new barrel must be test-fired to ensure that not only does it shoot accurately enough, but also that the sights are zeroed and that the rifle performs with sufficient reliability. (The only acceptable standard is 100%.) A new barrel is not like changing the oil in a car. The replacement must be tested.

Function-testing a rifle on the range is not the same as getting a recalcitrant rifle working in a shooting incident. On the street, getting the rifle working quickly, or safely disposing of it and using another weapon, is paramount. At the range, uncovering the origins of the fault is the prime consideration. (That, and safety.) When a rifle malfunctions on the range in a testing session, your immediate response should be to stop all activity. Inspect the rifle and note the condition of all parts, the locations of all controls, and the position and status of the bolt and carrier.

As an aside, as I was writing this chapter I happened to have a link to a video on the internet sent to me. I watched as some poor guy was firing an AR. He had a problem, yanked the charging handle and pulled the trigger. Nothing happened. So he hammered the forward assist. Nothing happened, so he swapped mags, worked the charging handle and hammered on the forward assist some more.

I thought to myself: “This cannot end well.” Then he pulled the trigger and the rifle disassembled itself. Typically with these events, he was not harmed. But the rifle was trashed.

Even if the zombies were pouring over the wall, his problem-solving process was flawed. If you are in a tough situation you may have to get a rifle working again quickly, but on a target range, any problem means you stop shooting and study the situation.

When firing you should note the direction and distance of the empty brass when ejected, as this is important information that can aid the diagnosis.

Officers: In a law enforcement setting, any weapon being “debugged” and serviced should have extensive notes taken on it during the process: ammunition used, to include lot number, firer, magazine type and number if the department gives it one.

Direction and distance of empty brass ejection, location and size of group fired, etc. An attitude that is well-known in the law enforcement and other communities is: “If it wasn’t written down, it didn’t happen.” All testing, changes and procedures used must be documented. For you, the non-sworn reader, that isn’t a career requirement, but the information gained can be very useful.

Another note: a big-name High Power shooter once wrote that he was checking his shooting log when he realized that his basic zero for long-range shooting on his rifle was now two minutes higher than it had been the season before. While his rifle was still shooting “X” ring accuracy, it clearly had a worn throat. (How is this obvious? When the bullet moves forward, it slows at the impact with the rifling.

That increases pressure, and velocity. His bullets were traveling further forward, getting less of a spike, and thus shorted on velocity. Less velocity meant more clicks up to hit the target at distance.) There was no way of telling how much useful life was left in the barrel, when the barrel would quit and stop shooting accurately. Accurate record-keeping allowed him to change the barrel before accuracy went away.

Most problems can be solved by one of the four problem areas discussed later, and rarely will a rifle need more than attention to the “Big Four”:

Weak extractor spring

Lack of lubricant

Loose carrier key

Faulty magazines

AR-15 Reassembly

The charging handle and carrier-bolt assembly can be installed in the upper before or after you connect the upper and lower receivers with the front take-down pin. If you install them before, insert the charging handle into the upper receiver.

Then press it upwards until it stops against the inside. Move it forward and back in the top track until the retention flanges on the charging handle drop into the access slot cut in the track. Then press the charging handle forward halfway. (If it drops, or tries to drop out, you missed the access slot. Try again.)

Take the carrier-bolt assembly. Make sure the bolt is fully forward by snapping your hand forward while holding tightly onto the carrier. The bolt, if not all the way forward, will slap forward to full extension. Insert the gas key into the charging handle recess and press the carrier forward.

Once it reaches the charging handle, the carrier will push the charging handle ahead of it. Press the carrier and charging handle fully forward, until the charging handle latch catches on the receiver. (There is a slot machined on the receiver for it to latch onto.)

Close the dust cover door. The charging handle latch, and the dust cover door, have enough retention to keep the carrier in the upper against gravity. However, if you have the rear of the upper receiver pointed down and something jars the upper, the catches may not hold. So while you have the upper off the lower, keep the muzzle level or pointed muzzle-down to keep the parts in.

Place the front takedown lug of the upper in between the flanges of the lower, and press the takedown pin from right to left to secure the upper. Then hinge the lower down until it is closed and press the rear pin across.

This article is an excerpt from Gunsmithing The AR-15.

Next Step: Get your FREE Printable Target Pack

Enhance your shooting precision with our 62 MOA Targets, perfect for rifles and handguns. Crafted in collaboration with Storm Tactical for accuracy and versatility.

Subscribe to the Gun Digest email newsletter and get your downloadable target pack sent straight to your inbox. Stay updated with the latest firearms info in the industry.