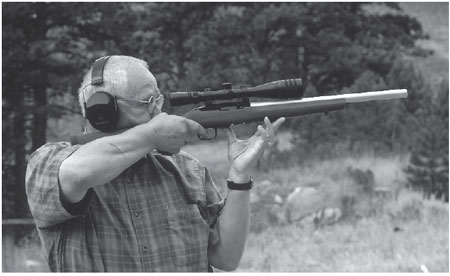

In order to launch projectiles with a high degree of precision and accuracy, the lock, stock, and barrel of your Ruger 10/22 must work together in a complementary way.

A rifle is a platform for launching projectiles. In order to launch projectiles with a high degree of precision and accuracy, the lock, stock, and barrel must work together in a complementary way. Although these factors are being discussed separately in this book, they are in fact interrelated. A stock of mediocre design may work fairly well with a heavy target barrel, but may not work as well with a slender, mediocre barrel. In the first case, the target barrel is less sensitive to what is holding it, so the system is more forgiving of the inadequacies of the stock. In the second case, the slender barrel of mediocre quality needs to be supported exactly right for it to shoot with greatest accuracy. This is due to barrel vibrations, and the stock helps to control vibrations (which are more pronounced with lightweight barrels).

Also, as a slender barrel heats up during repeated firing, it needs to be held in the most advantageous way. Even when the effects of barrel and stock are controlled, there is still the advantage of having a good trigger. If it requires excessive force to cause the trigger to release, movement of the rifle may negate some of the quality of the barrel and stock. Therefore, while this chapter will deal with barrels for the Ruger 10/22, the other components have a symbiotic effect on accuracy.

Many of the technical characteristics of barrels were discussed in Chapter 2. Therefore, this chapter will describe additional features of barrels and provide a survey of the types of barrels that are available to the shooter who is customizing a Ruger 10/22.

Factory Barrels

Factory barrels for the Ruger 10/22 are produced in several variants. By far the most common is the standard weight 18.5-inch blue version that has open sights on the barrel. A stainless steel barrel is also produced in the same configuration. The Ruger 10/22 Target model is produced with a barrel that is 20 inches long and 0.920-inch in diameter. This heavy, hammer-forged barrel is available in both blue and stainless steel. No sights are mounted on the target barrels in accord with their intended use. The Ruger 10/22 Rifle has a 20-inch barrel while the Compact Rifle has a barrel that is 16.5 inches long. One variant of the Ruger 10/22 has become known as the “Wal-Mart” rifle because they are most often found in the stores of this enormous merchandiser. Ruger produces the rifles to the specifications of Lipsey’s, Inc. of Baton Rouge, LA who is one of the major suppliers of firearms to Wal-Mart. The stainless steel barrel of this rifle is 22 inches long, and it has a slender profile. Open sights are provided on this barrel.

Firearms manufacturers who produce millions of barrels for rimfire rifles selling at modest prices cannot afford to make a barrel that is of the highest quality. If they did, the price of the rifle would have to be twice as high, and sales would most certainly suffer. There must be a balance between quality and cost. Please do not misunderstand what this means. Factory barrels on rimfire rifles, including the Ruger 10/22, are perfectly adequate for most sporting uses of such firearms. However, they do not have the close tolerances and exquisite finish required to produce the highest possible accuracy. To underscore this, we have found that simply installing a good aftermarket barrel may cut the group size produced by a Ruger 10/22. However, for many shooters, the factory barrel is the only one they will ever use, and their 10/22s will perform all the tasks required of the rifles. An analogous situation exists in the area of photography. Many people who own cameras that will accept interchangeable lenses take all their photographs with the lens that came with the camera. Users of all sorts of equipment readily accept such limitations. However, many of the photographs in this book could not be taken without having more specialized equipment. Higher levels of performance and specialized applications require the use of special accessories in many fields of endeavor. Fortunately, the user of a Ruger 10/22 has an enormous range of products available to enhance the accuracy of the rifle.

Changing Barrels

If there is one user friendly aspect of the Ruger 10/22 compared to other rimfire semiautos it is the ease with which the barrel can be removed and another attached. On most rimfire rifles, the barrel is press-fitted in the receiver, and a retaining pin is placed laterally through the receiver and a notch in the barrel shank. Expensive rimfire rifles sometimes have the barrel threaded into the receiver, but this requires cutting the threads on the barrel tenon or shank and in the receiver, which is a slower, more expensive process. It is, however, the method that is generally acknowledged to be the best although some extremely accurate rimfire rifles do not have barrels attached in this way.

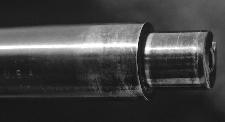

The barrel on a Ruger 10/22 is held in place by two large screws that require a 5/32- inch Allen wrench to turn. These screws pass through a V-shaped steel block that fits over an extension at the bottom of the receiver while a beveled surface on the block makes contact with the beveled surface of a notch that is cut transversely across the bottom of the barrel. When the screws are tightened, the block pulls the barrel back into the receiver holding it rigidly in place. The result is solid barrel attachment without having to cut threads on the barrel and inside the receiver.

There are several cautions that need to be made about changing barrels on Ruger 10/22 rifles. First, although the barrel, the block that engages it, and the locking bolts are made of steel, the receiver is not. Receivers on Ruger 10/22 rifles are made of an aluminum alloy. It would be possible to apply torque to the retaining bolts to the point that the threads in the receiver are damaged or stripped. Do NOT try to tighten the locking bolts too tightly! Second, since the receiver is made of aluminum, repeated removal and attaching the barrel causes some wear on the threads in the softer receiver. Aluminum is not a metal that is very resistant to abrasion so the threads on the steel locking bolts abrade the aluminum somewhat each time they are removed and attached. Having changed barrels on two of our Ruger 10/22s a large number of times during the testing program carried out to produce this book, it is easy to see that the locking bolts now fit much looser in the receiver as they are inserted. Do not change the barrel on a Ruger 10/22 unless it is necessary to do so! The threads in the receiver may be worn excessively as a result of repeated barrel changing.

Installing Aftermarket Barrels

With the receiver of the Ruger 10/22 being made of cast aluminum, there is a considerable amount of variation in dimensions. As a result, the receiver of one of our rifles will accept barrels that will not even begin to enter the receiver of another. Some aftermarket barrels are produced with tenons (or shanks) having a diameter that tends toward the maximum allowed while some receivers may have openings with minimum dimensions. It is also possible that either the barrel extension or the hole in the receiver (or both) may not be perfectly round. As a result, it is not uncommon to find that a particular barrel does not slide easily into the receiver. We have found that this is by no means uncommon and does not indicate a defect in the barrel. In fact, some manufacturers deliberately make barrel tenons with maximum dimensions so that they will need to be polished and individually fitted to receivers. However, do NOT attempt to pull an oversize barrel into the receiver by means of excessive tightening of the locking bolts! If you do so, there is a very real probability that the screws will damage the threads in the receiver or strip them altogether. The locking screws provide a secure hold of the barrel to the receiver when they are fully engaged, but they should not be used as the means to pull a tight barrel into the receiver when they are only partially engaged.

If the barrel extension will not enter the receiver without undue force, you may have to polish it with emery cloth or sandpaper. If you do, make sure that you polish it uniformly around the barrel extension to keep it round. Be careful not to remove more metal around the extractor cut because there is less bearing surface there as the emery cloth is pressed against the barrel. Aftermarket barrels from some sources are accompanied by instructions on how to polish the barrel tenon.

As you polish the barrel tenon (see Chapter 6), try frequently to fit it into the receiver. Although the cut for the locking block is across the bottom of the barrel, try inserting the barrel with the cut on top then rotating it in the receiver. In this way you can determine whether the barrel is equally tight all the way around or whether it is tight only in one orientation. If either the hole in the receiver or the barrel extension is not round, this will be revealed as you try to rotate the barrel while it is inserted into the receiver.

After you have nearly completed the polishing of the tenon of a blue barrel (you will know this by how tightly the barrel fits), you will need to blue the area that has been polished. Remove any oil from the surface by rubbing it with a small amount of alcohol or other solvent. Apply the bluing solution with a small piece of cloth while observing the cautions and directions given on the bottle. Bluing will require several applications of the solution. However, after the polished surface area is lightly blued by only one or two applications, insert it in the receiver and rotate it. When you remove it, you will be able to see clearly where contact is excessive because the freshly applied blue will be rubbed off from those areas. You now know where to administer that final bit of polishing to achieve a perfect fit of the barrel to the receiver. When this is complete, finish the bluing process and rinse off any remaining solution and salts. Apply a light coat of oil or other protecting solvent and attach the barrel to the receiver.

Hopefully, the process described above does not sound complicated because it isn’t. In fact, it may not be necessary at all. Of the many barrels that we have attached to our 10/22 receivers, only three or four have required any fitting. We have also noted that some barrels will slide easily into one receiver but not into a different one. The method of attaching the barrel to the receiver of a Ruger 10/22 allows the fit of the barrel in the receiver to be somewhat sloppy and the rifle to still function perfectly and give good accuracy. The beveled wedge and barrel recess still make for rigid attachment.

Accuracy

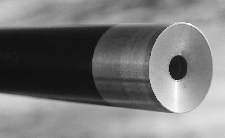

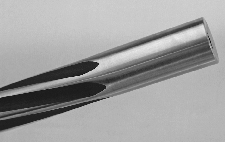

Several factors come into play in determining how accurately a rifle barrel shoots. Some of these factors will be reviewed briefly. One of the most important is the crown (the muzzle). The muzzle must be perpendicular to the axis of the bore for best accuracy. If it is not, the bullet will be in contact with the longer side of the barrel after it has cleared the shorter side. This results in tipping of the bullet, which has an adverse effect on accuracy.

Another factor that determines the accuracy produced by a rifle barrel is related to the chamber. In order to allow almost any cartridge to be chambered, factory barrels are produced with chambers that are somewhat larger in dimensions than those that would give best accuracy. When a cartridge is placed in a tight chamber, it is held more closely aligned with the bore than when it is in a chamber in which it fits loosely. A bullet that starts out tipped in the bore will be deformed (more than simply the engraving by the rifling) so accuracy suffers. Many custom rifles that are built specifically for benchrest competition have particularly tight chambers. However, a chamber that is tight enough to prevent entry of some cartridges would not be a good choice for a hunting rifle. As will be discussed in Chapter 11, we found that it was very difficult to chamber certain types of cartridges in some of the match grade barrels. As a result, barrels having match chambers may fail to feed some types of ammunition. If this occurs, try other types of ammunition.

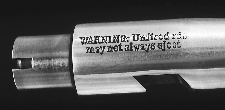

Many of the fine aftermarket barrels have a statement on them to the effect that unfired cartridges may not eject from the barrel. The reason for this is that the rifling extends back to the mouth of the chamber and bullet engages the rifling. As a result, there may be enough traction on the bullet so that as the bolt moves back the extractor slides over the rim of the cartridge rather than pulling the cartridge out of the chamber.

The breech face of a rifle barrel should be perpendicular to the bore. If the rim of a cartridge fits against the rear edge of the chamber, it will be tipped if that edge is not perpendicular to the bore. When the cartridge is fired, the bullet will leave the chamber somewhat tipped in comparison to the axis of the bore. Because crushing the priming mixture held in the rim fires a rimfire cartridge, the rim must fit against the rear edge of the chamber in a fixed, reproducible way. Therefore, the rear edge of the chamber must not only be perpendicular to the bore, but also it must be smooth.

Having addressed some of the issues related to crowns and chambers, it should also be remembered that the bore and rifling are also vitally important. Inexpensive rimfire barrels produced by factories are not noted for being mirror smooth. In some cases, they can be lapped (see Chapters 2 and 4) to smooth the interior surfaces, but many of the barrels produced by custom barrel makers are the result of slow, painstaking work. The bores and rifling are already very smooth and held to tighter tolerances than on factory barrels. Some are even hand lapped. That is why it is not uncommon to spend more for a high-grade replacement barrel than the original cost of a complete Ruger 10/22.

In later chapters, a great deal of data will be presented to show the accuracy that we obtained from a large number of custom rifles. Keep in mind that not all barrels function equally well with all types of ammunition. It is not uncommon to find that barrel A functions better than barrel B with one type of ammunition while the reverse is true with a different type of ammunition. This is natural, and it shows that the shooter should experiment with several types of ammunition to evaluate accuracy regardless of the barrel being used. However, as will be shown later, four or five types of ammunition gave outstanding accuracy with almost all of the aftermarket barrels.

Types of Aftermarket Barrels

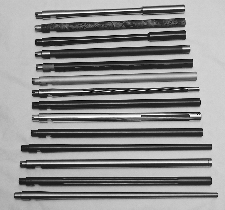

The number of sellers of aftermarket barrels is large and as a result, the number of types of barrels offered is enormous. This is an area where it is possible for the shooter to swap the factory barrel for one of almost any configuration. Perhaps the most common type of barrel installed on Ruger 10/22s is the so-called target barrel, which usually has a 0.920-inch diameter. Such barrels are available in a range of prices that reaches from less than $100 to well over $300. Moreover, target barrels are available in both blue and stainless steel, with or without flutes. Almost all of the major suppliers of barrels for the Ruger 10/22 offer one or more models of this general type. Heavy barrels from Adams & Bennett, Butler Creek, and Green Mountain are among the more economical models, but if you refer to the test results presented in Chapter 11, you will see that they give excellent accuracy. Toward the upper end of the price range are the fine barrels produced by Jarvis, Kidd Innovative Design, Lilja, and Shilen. We have used several of these superbly accurate barrels with complete satisfaction.

Installing a target barrel on your 10/22 will require a stock with a barrel channel to accommodate the barrel of larger diameter. This means that you must either modify the factory stock or get one with the large barrel channel. If you choose to modify the factory stock, the barrel band will not fit over the target barrel. To modify the barrel channel, you will need to take a short section of a dowel rod of appropriate diameter and wrap it with sandpaper. With this sanding device, you can now (laboriously) work on the barrel channel by removing wood until it will accept the target barrel. The other alternative (which is probably more often exercised and more satisfactory) is to buy a new stock having a 0.920-inch barrel channel from one of the aftermarket sources. We have discussed stocks in detail in Chapter 7.

Aftermarket barrels are also produced which have the same (or very nearly the same) profile as the factory barrel. These so-called standard weight barrels can be used with the factory stock or with another that has a barrel channel of the same width. As is the case with target barrels, standard weight barrels are available in both blue and stainless steel. Several versions are available with flutes that are either straight or that spiral around the barrel. It might be assumed that the heavy target barrels would be much more accurate than those of standard weight, but this is not always the case. You may achieve as much improvement in accuracy as you desire with a lighter weight barrel. We have worked with these lighter weight barrels from Green Mountain, Jarvis, and Lilja. Studying the data shown in the tables in Chapter 11 will show just how accurate these barrels are.

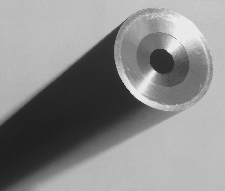

Although many aftermarket stocks are available with barrel channels that fit barrels of factory dimensions, some owners of a Ruger 10/22 may want to utilize the factory stock. That limits the choice of barrels to those that have the standard contour. However, another popular type of barrel that fits the factory stock is the muzzle weighted or running boar model. This barrel has a diameter that matches that of the factory barrel except for the last four or five inches where the diameter increases to 0.920 inch. The heavy section near the muzzle adds weight forward of the hands which aids in steady holding. It also makes it easier to have a smooth swing when aiming at a moving target. We have used three outstanding barrels of this type, a Green Mountain blue version in .22 WMR, a Ranch Products blue .22 LR barrel, and a stainless Volquartsen in .22 LR.

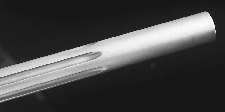

Another type of barrel that appeals to many shooters is what might be called a “compound” barrel. This type of barrel consists of an inner rifled tube made of steel having a small outside diameter that is surrounded by an outer sleeve made of some material of lighter weight. The most common outer sleeves are made of aluminum or a carbon fiber composite material. Barrels of this type generally have a 0.920-inch diameter and are used with a stock having a barrel channel of that width. An outstanding barrel of the aluminum sleeved type that is available in all four rimfire calibers is the Majestic Arms Aluma-Lite barrel which has an inner barrel made by Lothar Walther. Although light in weight, they perform like true heavyweights.

An example of a barrel having a carbon fiber sleeve is the MagnumLite® barrel from Magnum Research which weighs only 12.8 ounces. These barrels are available in .22 LR, .22 WMR, .17 Mach 2, and .17 HMR calibers. Another fine carbon-sleeved barrel is the Ultra-Lite® marketed by Butler Creek which is produced with open sights. The Featherweight version from Butler Creek is furnished without sights. Both have Bentz type match chambers.

An unusual barrel of the sleeved type is available in .22 LR from Whistle Pig. This barrel features a highly polished outer sleeve made of aluminum that is fluted. Barrels are available with the insides of the flutes finished with enamel in a choice of colors. This provides a barrel that is light in weight (about 18 ounces), has a striking appearance, and gives excellent accuracy. Another producer of unusual sleeved barrels is Tactical Solutions. These barrels weigh a pound or less and are available in red, purple, green, blue, black, gray, and camo colors. These barrels are also available with or without flutes in .22 LR and .22 WMR calibers.

A tensioned barrel also consists of an inner sleeve that is held in an outer tube. In this case, the sleeve is constructed so that it is long enough to push forward on the muzzle end of the barrel while pushing backward on the breech end. This puts a tension on the barrel, which is supposed to help control the vibrations that occur during firing. Tensioned barrels are available from Volquartsen among others.

Recently, Green Mountain introduced a remarkable type of barrel in .22 LR and .22 WMR for the Ruger 10/22. Those barrels, known as the Aero Series, have a slender stainless steel barrel measuring just 16 inches in length, which is surrounded by a metal sleeve. The 0.920-inch diameter metal sleeve extends about 7/8-inch beyond the end of the barrel, and it has oval slots throughout its length. The overall length of the sleeved barrel is 17 inches, and sleeves are available in black, green, blue, yellow, red, and polished aluminum colors. A Competition model in .22 LR has a barrel weight that is contained within the shroud.

The stainless steel inner barrel of the Aero Series has shallow flutes, a Bentz-type chamber, and a rifling twist of one turn in 15 inches. It also has an 11-degree muzzle crown and is treated to relieve stress. Two O-rings around the chamber area are used to separate the shroud from the barrel. Additionally, the sleeves are intended to be free floating, and to give the proper clearance, they are supplied with a shim that can be placed under the lug where the barrel attaches. This lifts the barrel very slightly at the rear to make the assembly free floating. Weighing only 21.6 ounces, the Green Mountain Aero barrel is well suited for building ultra light rifles based on the Ruger 10/22 action.

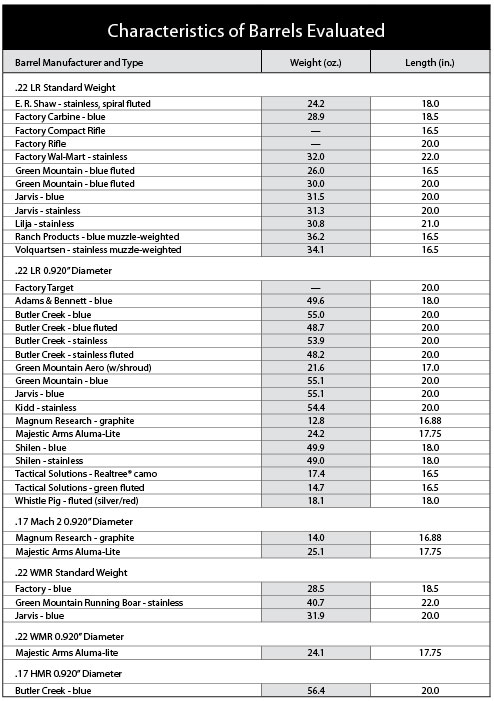

It is not unusual for a given manufacturer to produce barrels in blue and stainless steel in different weights and lengths as well as sleeved barrels. Given that a manufacturer may produce as many as eight or ten types of barrels, the number of available options must run in the hundreds. Although we did not approach this number of barrels used in the tests, the number was still substantial. The accompanying table shows data for the barrels that were used in experiments as part of the data collection for this book.

As can be seen from the table of specifications, barrels generally fall into two categories based on barrel dimensions depending on whether they have the contour of the factory barrel or a 0.920-inch diameter. Although several of the barrels have a diameter of 0.920 inches, they are ultra light models. When selecting a barrel, keep in mind that the barrels fall into three general categories that can be considered as ultra light (under 25 ounces), standard weight (25 to 35 ounces), and heavy weight (over 48 ounces). Depending on the intended use for your custom Ruger 10/22, you may be more concerned with the weight than with diameter. Be assured that highly accurate barrels are available in all of the classifications either by weight or by diameter. When it comes to barrels, there is something for everyone who customizes the Ruger 10/22.

This is an excerpt from Customize the Ruger 10/22.

Next Step: Get your FREE Printable Target Pack

Enhance your shooting precision with our 62 MOA Targets, perfect for rifles and handguns. Crafted in collaboration with Storm Tactical for accuracy and versatility.

Subscribe to the Gun Digest email newsletter and get your downloadable target pack sent straight to your inbox. Stay updated with the latest firearms info in the industry.

![Best Concealed Carry Guns In 2025 [Field Tested] Wilson Combat EDC X9S 1](https://gundigest.com/wp-content/uploads/Wilson-Combat-EDC-X9S-1-324x160.jpg)

![Best 9mm Carbine: Affordable PCCs [Tested] Ruger Carbine Shooting](https://gundigest.com/wp-content/uploads/Ruger-Carbine-Shooting-100x70.jpg)

![Best AR-15: Top Options Available Today [Field Tested] Harrington and Richardson PSA XM177E2 feature](https://gundigest.com/wp-content/uploads/Harrington-and-Richardson-PSA-XM177E2-feature-100x70.jpg)

[…] Barrels for the Ruger 10/22 Installing A 10/22 Barrel RUGER10/22 REPLACEMENT BARRELS […]

[…] pretty certain you will find it very useful and informative. Please cut and paste the link below: Barrels for the Ruger 10/22 | Gun Digest – The World's Foremost Gun Information Authority Good luck, hope the information […]